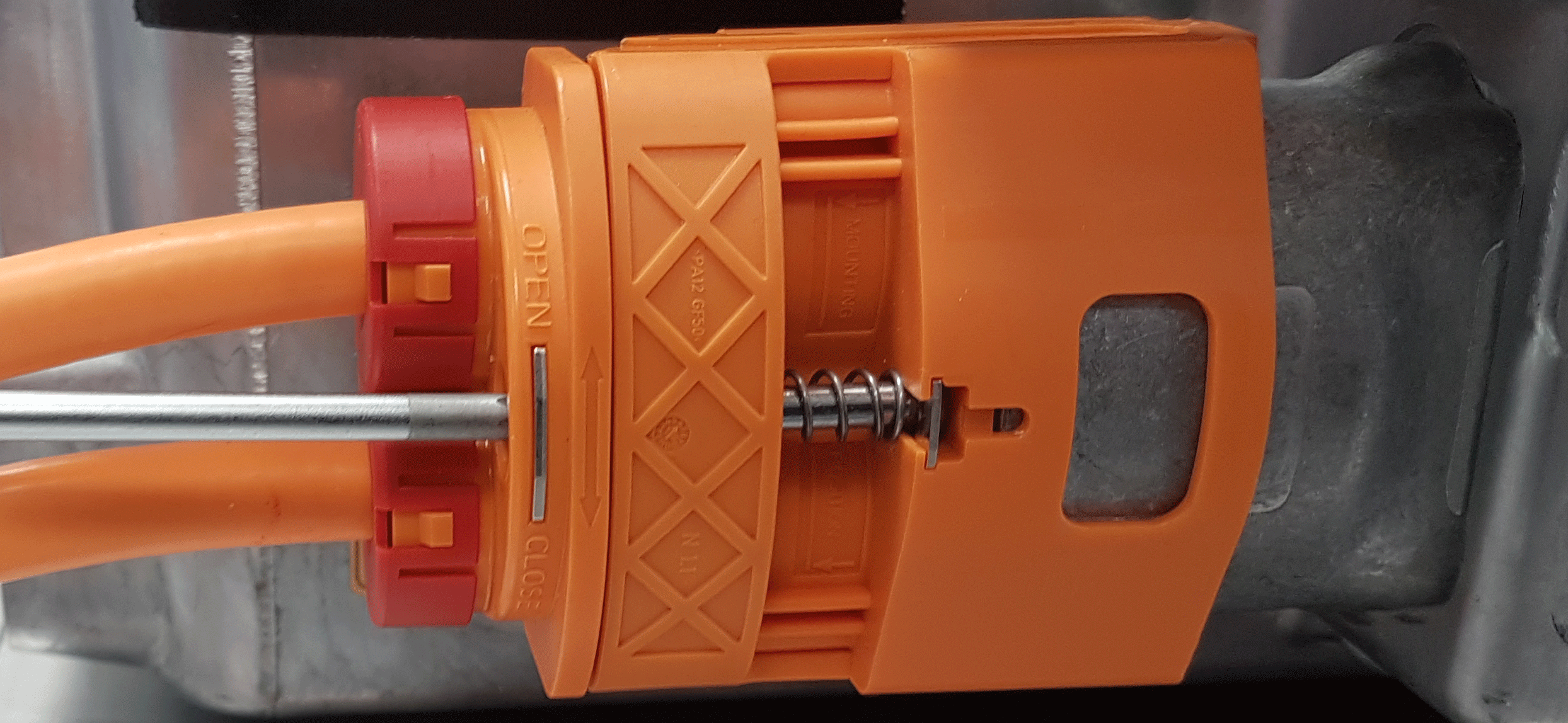

The increasing number of electric and hybrid vehicles illustrates the importance of the requirements for a safe and reliable high-voltage network in cars. An important and yet for many not very present point is an efficient and above all safe cabling. The high-voltage cable, which is made up of several layers, is designed for high load capacity and durability. The HV (ev) connectors in the high-voltage network of an electric car must not form any weak points. This applies in particular to contact protection according to IPXXB as required by ECE R 100. Not only trained electrical specialists and specialists for high-voltage systems (FfHV) qualified in high-voltage training, but also rescue workers and first responders must be able to clearly assign HV (ev) plug connections at the scene of an accident and safely disconnect them if necessary.

Reliable contact protection is a prerequisite for a safe working environment when working on the electric car.

Safe (ev) high voltage systems need safe connectors

(ev) high voltage connectors must be designed to withstand vibration and must not age prematurely in order to avoid electrical defects during driving even after many years. The connectors are designed for the specific power profiles, but also for the different environmental factors in the HV (ev) vehicle. The decisive factor is that the connectors fit into the overall system and can be produced economically. The electric vehicles on our roads are still young model years, but today’s electric cars are tomorrow’s older used cars.

Durable (ev) high voltage connectors create reliability

The challenge for developers of high-voltage connectors is great: The connectors must withstand voltages of up to 1000 volts. They must not allow arcing or leakage currents to occur and must exclude problematic contact resistances. A wide thermal tolerance is also required: HV (ev) connectors must withstand temperatures between -40 °C and +170 °C. In addition, electromagnetic compatibility is important in order not to negatively influence any electrical components in the vehicle’s high-voltage network and low-voltage network. Due to the mobile environment in which (ev) high voltage connectors have to prove themselves, reserves have to be planned during development to ensure high operational reliability even under extreme loads. Because at the end of the day, the safety of employees in production, workshops and, of course, customers is paramount.

Leave A Comment